Launched 1999 as XK-90, in 2015 became XK-100.

155 max RPM is standard. Higher is optional.

Diesel is standard, electric power is optional.

Variable speed, zero to max - No two-speed hydraulics.

7,000 ft-lbs max torque - Way exceeds pipe rating.

100 tons load rating - both static & rotating.

RPM Readout Coming Soon - Simple cheap hanging cable, hazardous location display on control panel.

Patented SafeBreak Sub Breaker for breaking out subs on trailer instead of dangerous pipe wrenches. Safe, easy, quick, and compact.

Patented 10,000 psi Washpipe Seal Assembly - 10,000 psi at Max RPM - Field reports seal life up to 2000 hours before changing seals and design underway to multiply that. Auto-lubricated for low friction and long seal life - No greasing required. Optional at extra cost. Necessary for long reach laterals, otherwise standard 5000 psi washpipe assembly is fine.

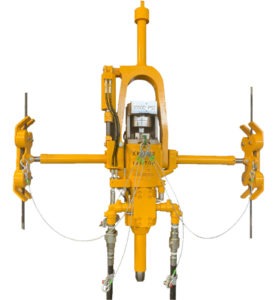

Patented Power Tilt - Tilt angle is easily set at rigup - Click lever forward, tilts to same angle throughout job. Click lever to rear, pipe floats to vertical while picking up. When tilt is not in use, swivel is held vertical by hydraulics, no rope or chain required. Auxiliary tilt valve on trailer assists safe loading/unloading.

Patented SafeLatch Torque Arms - See separately in website. These quick-connect torque arms will soon be standard, allowing personnel to quickly and safely latch/unlatch the torque arm rollers from the wire ropes. No falling objects since no wrenches or parts removal required.

Optional Parallel Torque Arms toward rear of mast - Keeps wire ropes out of rig floor space.

Patented Safety Valve - Prevents downtime if someone forgets to hook up the drain hose.

ScopeDown Torque Track coming soon. See separately in website. No rigdown labor required. Scopes down with mast, lays down and travels with mast. Numerous patents issued and pending.

One powered hose reel handles all hydraulic hoses.

Optional Air Brake - Reacts max swivel torque, simple.

SafeBreak breakout wrench - Mounted compactly to swivel rack on trailer, this unit is easily deployed to breakout subs and TIW valves.

10,000 psi Washpipe Seal Assembly

Our patented seal assembly is rated at 10,000 psi at Max RPM with minimal torque drag. It is automatically pressure-lubricated and requires no greasing. This is a uniquely engineered design, very different from conventional concepts using metal rings and rubber V-rings. We have received happy field reports of up to 2000 hours before changing seals. Nonetheless, we continue engineering and we expect seal life to improve greatly.

Swivel Tilt

XK power swivels include our patented power tilt function. The driller easily sets the tilt angle stop at rigup to match the pipe angle in the V-door, then the swivel tilts to the same angle throughout the job when he clicks the handle forward. Clicking to the rear position floats the pipe to vertical during pick up. When tilt is not in use, the power swivel is hydraulically held vertical for easy stab with no need for a rope or chain. Our customers are very pleased with the safety benefits and time savings.

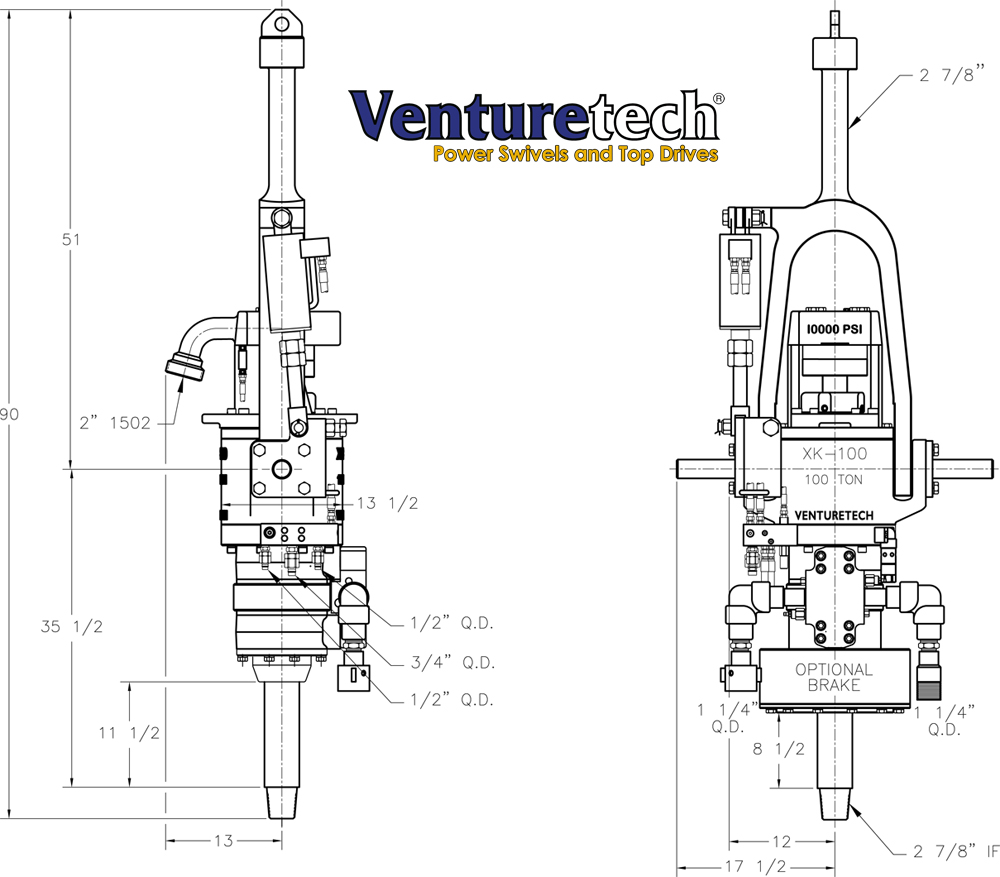

XK-100 Specifications

| Max Torque | 7,000 FT-LBS |

| Max Speed | 150 RPM |

| Max Static Load Rating | 100 TONS |

| 100 RPM Dynamic Load Rating | 100 TONS |

| Max Circulating Pressure | 10,000 PSI |

| Gooseneck Connection | 2-1/2" 1502 Union |

| Fluid Passage Bore Thru Stem | 2" I.D. |

| Standard Stem Connection | 2-7/8" I.F. |

| Standard Saver Sub Connection | 2-7/8" I.F. |

| Weight | 1,500 LBS |

XK-100 Power Units

Trailer Power Units

Two-axle trailers are arranged with rugged fender tanks for best road balance and serviceability. Units have electric brakes on both axles. Gooseneck or bumper hitches are optional, and spare tire is included. Hydraulic powered multi-hose reel is standard with 100 foot hydraulic hoses, and reel will accept 200 feet if required. The unit also includes a variable displacement piston-type hydraulic pump to allow any swivel speed desired. Caterpillar engines are standard, others are available.

This is Cecil Kirkland, a good customer and a friend, owner of Navajo Fishing Tools. On his 87th birthday, I called Cecil on his cell. I said, “Happy Birthday, Cecil, this is Larry and I’d like to come by your office and shake your hand.” He said, “Larry I’d sure like to see you, but I’m on a rig in Madisonville - I’m running tools in the hole…” That’s the best story I’ve ever heard about how to grow old doing what you love.

Skid Power Units

Rugged oilfield skids are designed for truck winching and are fully floored. Heavy-duty dual tank design uses minimum floor space, and all equipment is arranged to allow easiest access for service. Hydraulic powered multi-hose reel is standard with 100 foot hydraulic hoses, and reel will accept 200 feet if required. The unit also includes a variable displacement piston-type hydraulic pump to allow any swivel speed desired. Overhead lifting frames are available for offshore crane lifting. Caterpillar engines are standard, others are available.

Air Remote Controls

Air remote controls are connected by a 50-foot umbilical. Stainless control panel features liquid-filled torque gauge, single handle control for variable speed & direction, auto-throttle, and power tilt. Also included are engine kill (fuel shutoff), emergency engine kill (air shutoff), plus torque release which allows safe unwind of the drill string before picking up. Additional emergency engine kill control is also located on the engine.

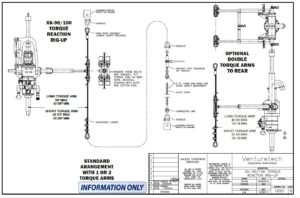

Torque Reaction Equipment

See above Safe Latch Torque Arms and ScopeDown Torque Track coming soon!

Two telescoping torque arms are included with every unit, and several length ranges are available.

Four self-lubricated sheaves roll up and down each wire rope stretched between crown and floor.

Safety cables protect rig floor people from falling objects in case anything comes loose.

Optional parallel torque arms are arranged toward the back of the mast which moves the wire ropes out of the way.

New Safe-Latch Torque Arms will become standard shortly. See front page of the website. Patent pending. Easy, quick, and safe to latch/unlatch the torque arm rollers from the wire ropes. No loose parts, wrenches, or falling objects.

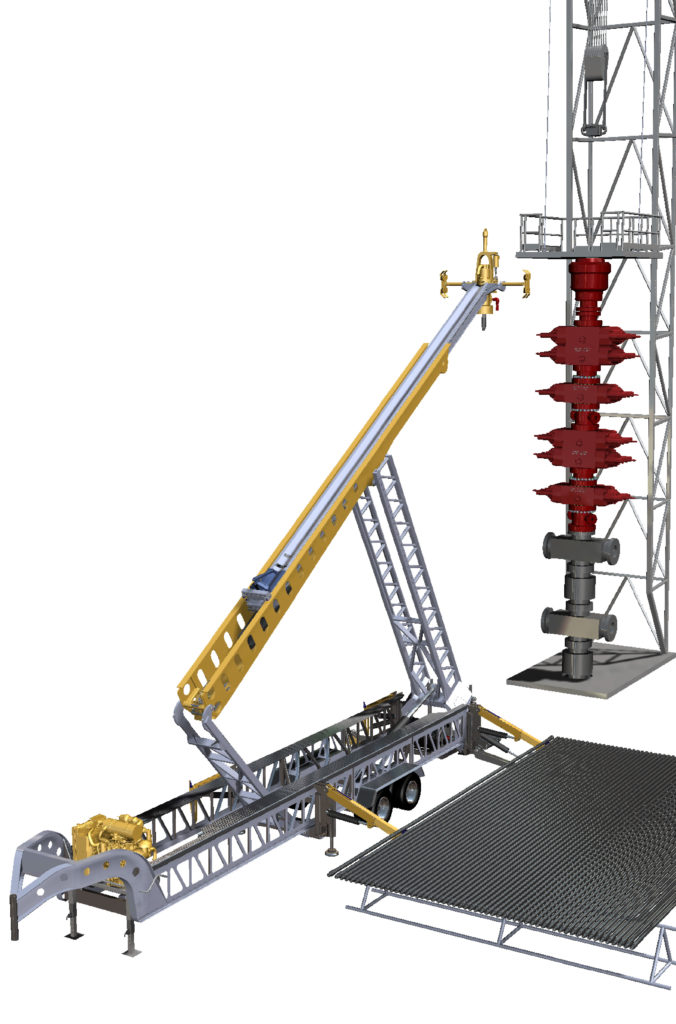

Announcing Super Handler™

The Super Handler™ is a radical combination of hydraulic pipe handler and power swivel!

Available with either the XK-100 or XK-150 power swivel.

Combining our power swivels with our unique pipe handler brings many benefits.

Remember, the cost of a Super Handler™ will be less than a pipe handler plus a power swivel because much duplication is eliminated.

Introducing now, launching soon.

We are still in engineering but are introducing Super HandlerTM now because companies are budgeting.

The first several patents are issued, more are pending, and others are filed as provisionals.