History of Power Swivel Development

By Larry Keast, P.E., Founder & CEO

This brief history is written from my experience since 1980, from researching Gulf Publishing's Composite Catalogs, and from stories told to me. Until Venturetech's XK power swivels, the only real player in this business was Bowen, although there were others along the way. There have also been a few non-engineering companies building poorly-designed equipment and even direct Bowen copies, and there have been fabrication packagers who buy a Bowen swivel and put it on their own power unit. In this brief history, I have only included power swivels designed and built by engineering-based manufacturing companies.

1948

The first power swivels appeared in the Composite Catalog. Baash-Ross and Homco each had a full page, and the S.R. Bowen Company offered one introductory sentence with no photo or other information. The largest of these first power swivels were rated up to 2000 ft-lbs torque, 40 tons capacity, and 31 rpm. Engines were up to 12 HP, and gear and vane-type hydraulic pumps and motors operated around 1000 psi.

1950

S.R. Bowen Company added a full catalog sheet on their "powered swivel".

1960

About 1960, Baash-Ross was bought by Joy Manufacturing and in 1962 they introduced 65 ton and 100 ton power swivels. Then about 1980, Baash-Ross introduced well-engineered upgrades of these models, calling them the PS-85 and PS-130. Sales never amounted to much because they were not hydraulic people and they did not build hydraulic power units. They had HPU's built by hydraulic suppliers so customer needs and features were never understood.

Other than Bowen, there were only three brands of power swivels designed and built in engineering-based manufacturing companies - Baash-Ross, Homco, and King. None ever competed effectively with Bowen after 1970, whose leadership was due to much more aggressive sales and marketing than the others.

1964

In 1964, Bowen introduced the 85 ton S-2 and the 120 ton S-3. Early Vickers piston-type hydraulic motors had to be bolted on from the inside of the gearbox before swivel assembly so field replacement was impossible.

Joy Baash-Ross only made power swivels until Varco bought Baash-Ross and discontinued power swivels altogether in the early 90's.

1970

In the 1970's, after not offering a power swivel for years, Homco developed their own ingenious power swivels, but they were too expensive and too large to be practical. They never got off the ground, and after a few years, Homco started buying Bowens for use in their service operations.

King Oil Tools has been known since the 50's for their complete line of water well and workover swivels, not power swivels. King introduced 90 and 130 ton power swivels in the late 70's, and some have been sold through the years, but they were never a major competitor.

1972

In 1972, Bowen Introduced the S-2.5 and in 1973, the S-3.5. The load ratings remained the same as the previous S-2 and S-3, and the appearance was almost the same, but the gearing and body castings were redesigned for higher torques. To increase torque, they used the new Sundstrand 5000 psi closed loop hydraulics including variable displacement pumps and fixed motors. This high pressure piston equipment was new to the oilfield at the time, and typical gear and vane-type pumps and motors were still limited to 2500 psi. It's important to note that the oilfield didn't understand that the new high pressure piston equipment was extremely dirt sensitive.

So the Bowen 2.5 and 3.5 have been around since 1972 - so long that their model numbers became generic around the world, - a fine thing for Bowen. As a result, field people incorrectly referred to other brands of power swivels by Bowen model numbers, and our early customers would ask if we make a 2.5 or 3.5. We explained those are Bowen's model numbers and our XK-90 and XK-150 swivels are quite different, having 50% more torque and rotating load capacity, plus no gears. Thankfully, our power swivels became popular, and after a few years, people started referring to our XK’s by our model numbers.

Typical of big companies growing by merger and acquisition, when IRI bought Bowen in the 90's, some marketing guru or committee made the ill-informed decision to change their power swivel model designations. The new goal was to give all their power swivels consistent model numbers reflecting the tonnage rating. That would have been a great idea in the beginning, before the model no's 2.5 and 3.5 became generic. So the S-2.5 was renamed S-85 for 85 tons, and the S-3.5 renamed S-120 for 120 tons. As part of this exercise, they changed their power units, using later engines, pumps, some lower cost components, and a complicated power hose reel destined for long term problems. The swivel heads remained unchanged. The world still refers to the 2.5 and 3.5, and we have even heard field people refer to the 4.5, logically thinking it meant Bowen's 250 ton, which it never did.

2000

Then when National-Oilwell bought IRI in 2000, they even deleted the Bowen name from their advertising, a name which had earned a respected reputation around the world for 50 years. Mr. Bowen must have rolled over in his grave.

This has all been very confusing, customers in the field don't understand, and no doubt most National-Oilwell-Varco people don't know this history.

Venturetech’s only business is power swivels, and for many years before our own power swivels, we made a living providing replacement parts for Bowen, Baash-Ross, and other brands no longer in production. But as a creative design engineer and inventor, I never wanted to copy the Bowen swivels, because that would be an insult to my creativity and to Mr. Bowen's hard work building his company. I suppose I'm a bit unusual since the oilfield is filled with companies copying the originator's products. It's all legal after the patents run out, and they probably make more money than we do, but I just wouldn't have any fun. I'm sure the original Bowen engineers would approve of our work, and it's not that their designs were bad, just different; and they didn't have today's hydraulic components to work with.

We have been successful because power swivels are the only product line we have focused on since 1980. All the other power swivel manufacturers, even today, are much larger and have many product lines unrelated to power swivels which dilute their attention and creativity.

Finally, I'm a long time hot rodder and gearhead, and I love cars, trucks, and engines. When I discovered this power swivel business niche had diesel engines, technical hydraulics, and remote pneumatic controls, it was very interesting to me, looked like fun, and seemed like something I could do with excellence. Thankfully, that has proven to be the case, and I'm grateful. I'm also grateful to have a great team of people who love this equipment. We enjoy working together to build first class machinery for our customers and we look forward to continued development.

About Pipe Handlers

Handling oilfield pipe has historically been a dangerous task, causing many injuries and deaths over the years.

Before hydraulic machinery, pipe was handled by manpower and winching from the rig floor – Obviously very dangerous.

In the 1950’s, specialized winch trucks were developed for pipe pickup and laydown.

A winch line from the truck was attached above the rig floor.

A pipe trough was suspended from pulleys rolling on this long hanging line.

Individual joints of pipe were placed in the trough which was pulled to/from the rig floor.

This was the new technology - obvious safety problems but faster and probably safer than previously.

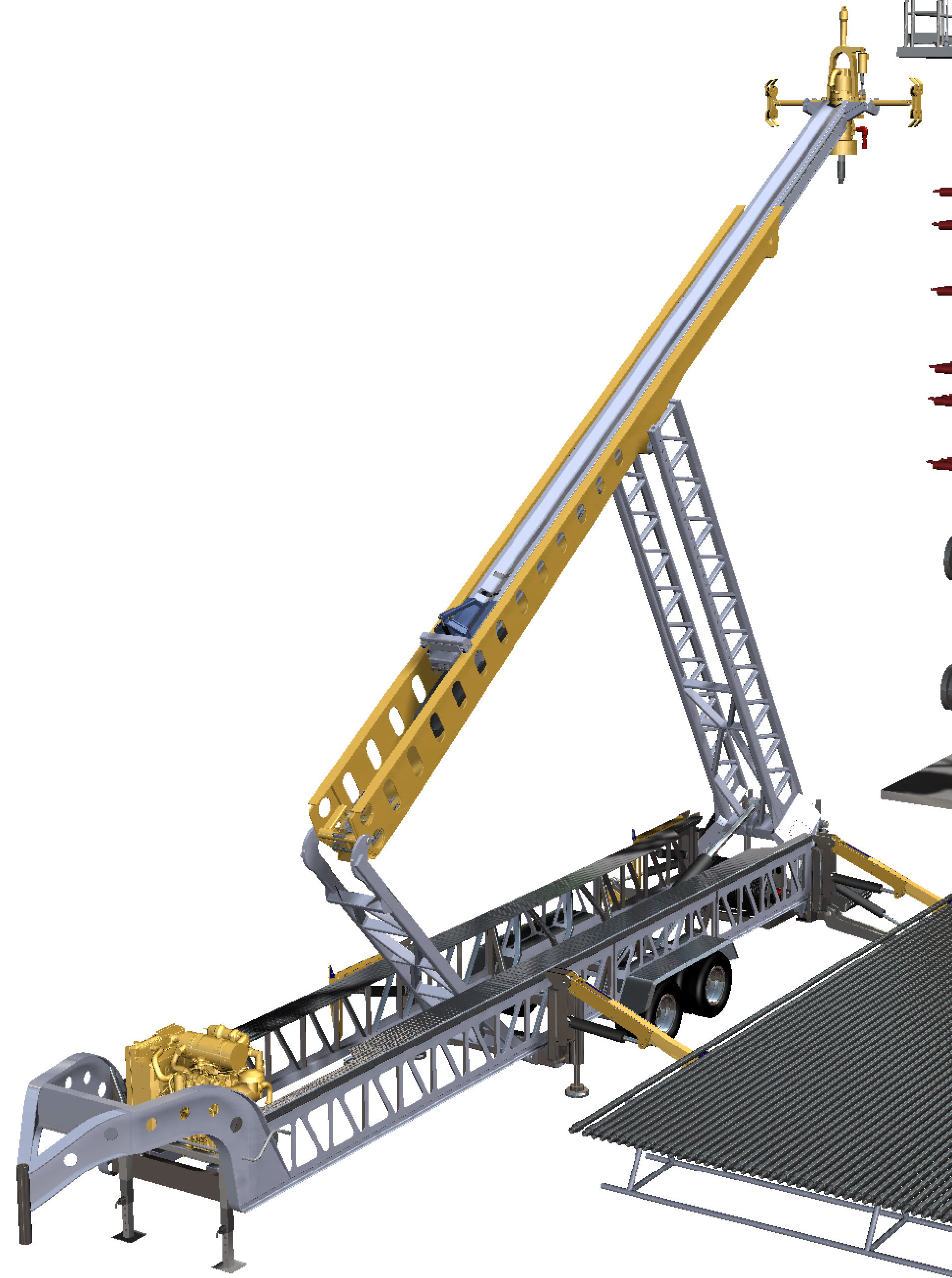

The first “hydraulic catwalk” was developed some 50 years later and became the forerunner of today’s variety of hydraulic pipe handlers.

These were commonly called hydraulic catwalks because they hydraulically moved the pipe-carrying catwalk up/down the V-door ramp to the rig floor.

Speed and safety were improved again.

Many competitive catwalk machines emerged from low cost welder-built machines to high tech extremely expensive machines.

Small to mid-size manufacturers like Hawker and Pipe Wranglers (both bought by Forum) emerged as some of the lead competitors.

Most such machines required dangerous manual work to install the main load-carrying pin in position to set the desired lift height.

As long reach horizontal drilling became common and reached beyond 24,000 feet, BOP stacks became taller with rig floors up to 40 feet.

Typical machines could not reach this high without installing extensions.

Such machines also required extensions to handle range 3 pipe lengths.

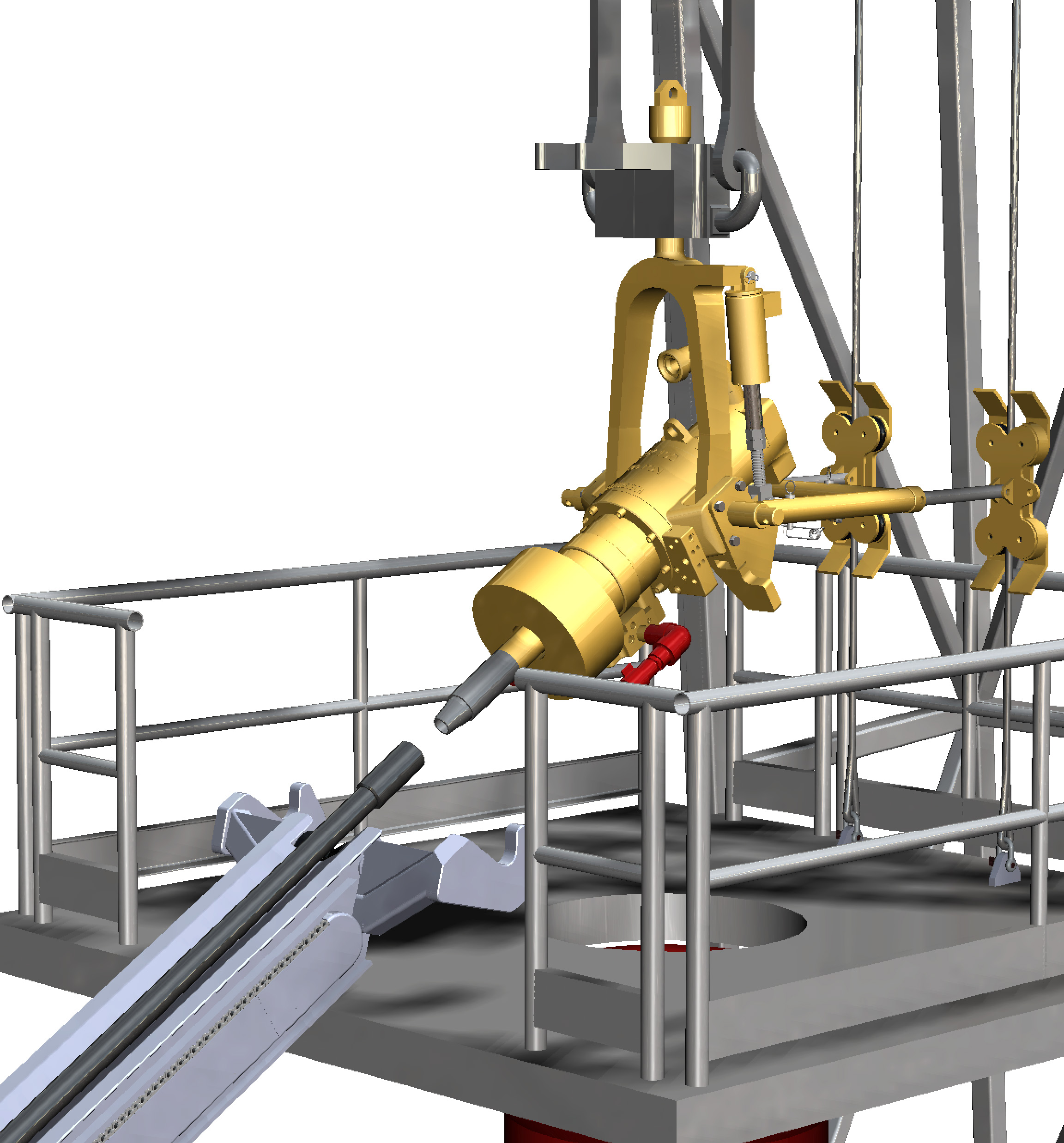

Now comes the Super Handler from Venturetech! Take a look at the list of features and advantages.