History of Top Drive Development

By Larry Keast, P.E., Founder & CEO

The top drive concept started with the first power swivels in 1948 which were the first hanging devices for rotating the pipe.

To read the history of power swivels, go to our section "About Power Swivels".

1960

About 1960, Baash-Ross was bought by Joy Manufacturing and in 1962 they introduced 65 ton and 100 ton power swivels. Then about 1980, Baash-Ross introduced well-engineered upgrades of these models, calling them the PS-85 and PS-130. Sales never amounted to much because they were not hydraulic people and they did not build hydraulic power units. They had HPU's built by hydraulic suppliers so customer needs and features were never understood.

Other than Bowen, there were only three brands of power swivels designed and built in engineering-based manufacturing companies - Baash-Ross, Homco, and King. None ever competed effectively with Bowen after 1970, whose leadership was due to much more aggressive sales and marketing than the others.

1964

In 1964, Bowen introduced the 85 ton S-2 and the 120 ton S-3. Early Vickers piston-type hydraulic motors had to be bolted on from the inside of the gearbox before swivel assembly so field replacement was impossible.

Joy Baash-Ross only made power swivels until Varco bought Baash-Ross and discontinued power swivels altogether in the early 90's.

1970

In the 1970's, after not offering a power swivel for years, Homco developed their own ingenious power swivels, but they were too expensive and too large to be practical. They never got off the ground, and after a few years, Homco started buying Bowens for use in their service operations.

About Pipe Handlers

Handling oilfield pipe has historically been a dangerous task, causing many injuries and deaths over the years.

Before hydraulic machinery, pipe was handled by manpower and winching from the rig floor – Obviously very dangerous.

In the 1950’s, specialized winch trucks were developed for pipe pickup and laydown.

A cable from the truck was attached above the rig floor.

A pipe trough was suspended from this hanging line by rolling pulleys.

Individual joints of pipe were rolled into the trough which was winched rapidly to and from the rig floor.

This was the new technology. Obvious safety problems but still probably faster and safer than before.

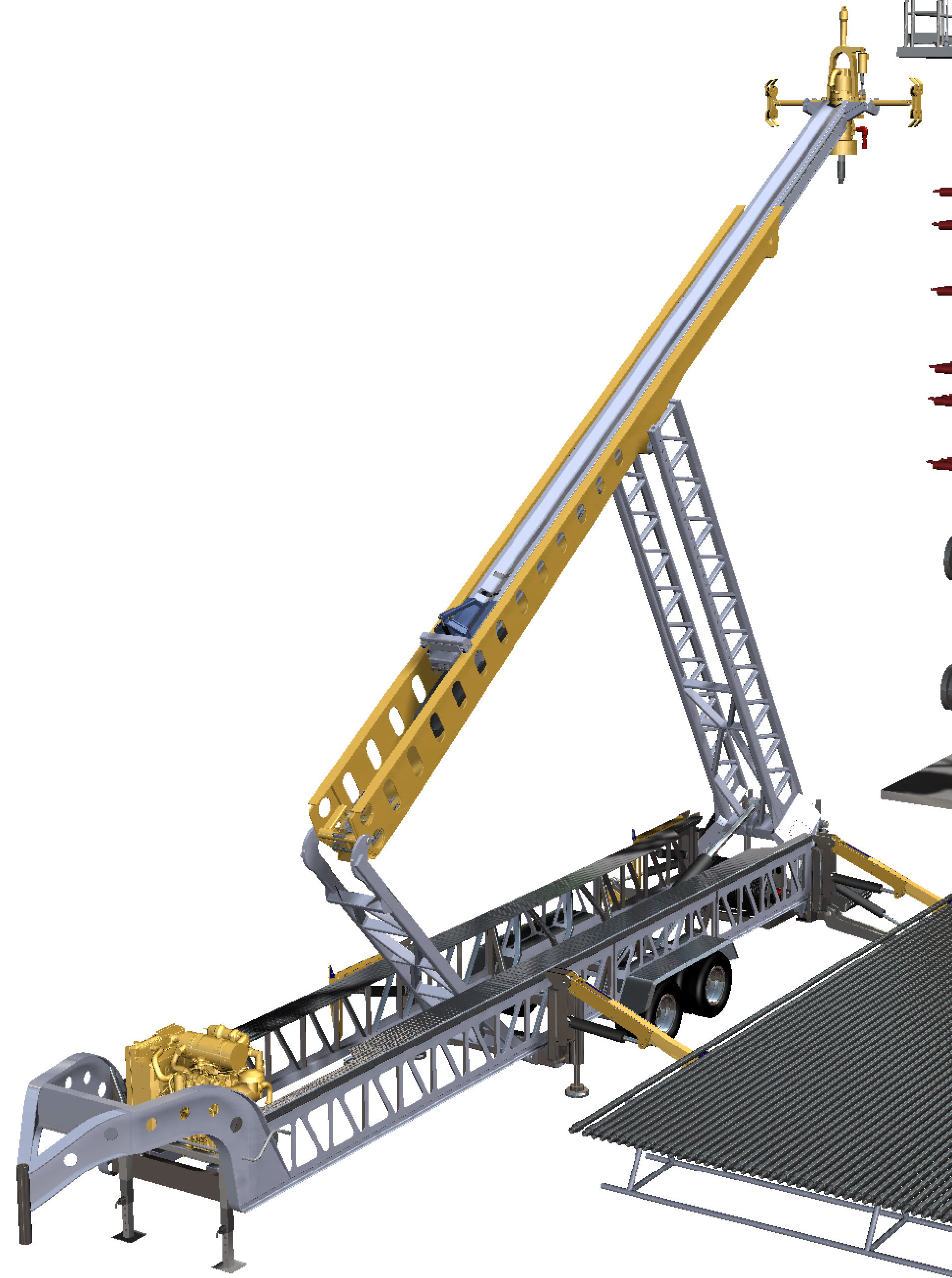

The first “hydraulic catwalk” was developed in the 90's and became the forerunner of today’s variety of hydraulic pipe handlers. These were commonly called hydraulic catwalks because they hydraulically moved the pipe-carrying catwalk up/down the V-door ramp to the rig floor.

Speed and safety were improved again.

Many competitive catwalk machines emerged - from low cost weldshop-built machines to high tech extremely expensive machines.

Small to mid-size manufacturers like Hawker and Pipe Wranglers (later Forum) emerged as some of the lead competitors.

Most such machines today require dangerous manual work to install the main load-carrying pins which also set the desired lift height.

As long reach horizontal drilling became common, BOP stacks became taller with rig floors up to 40 feet.

Typical machines today cannot reach this high or handle range 3 pipe without installing extensions.

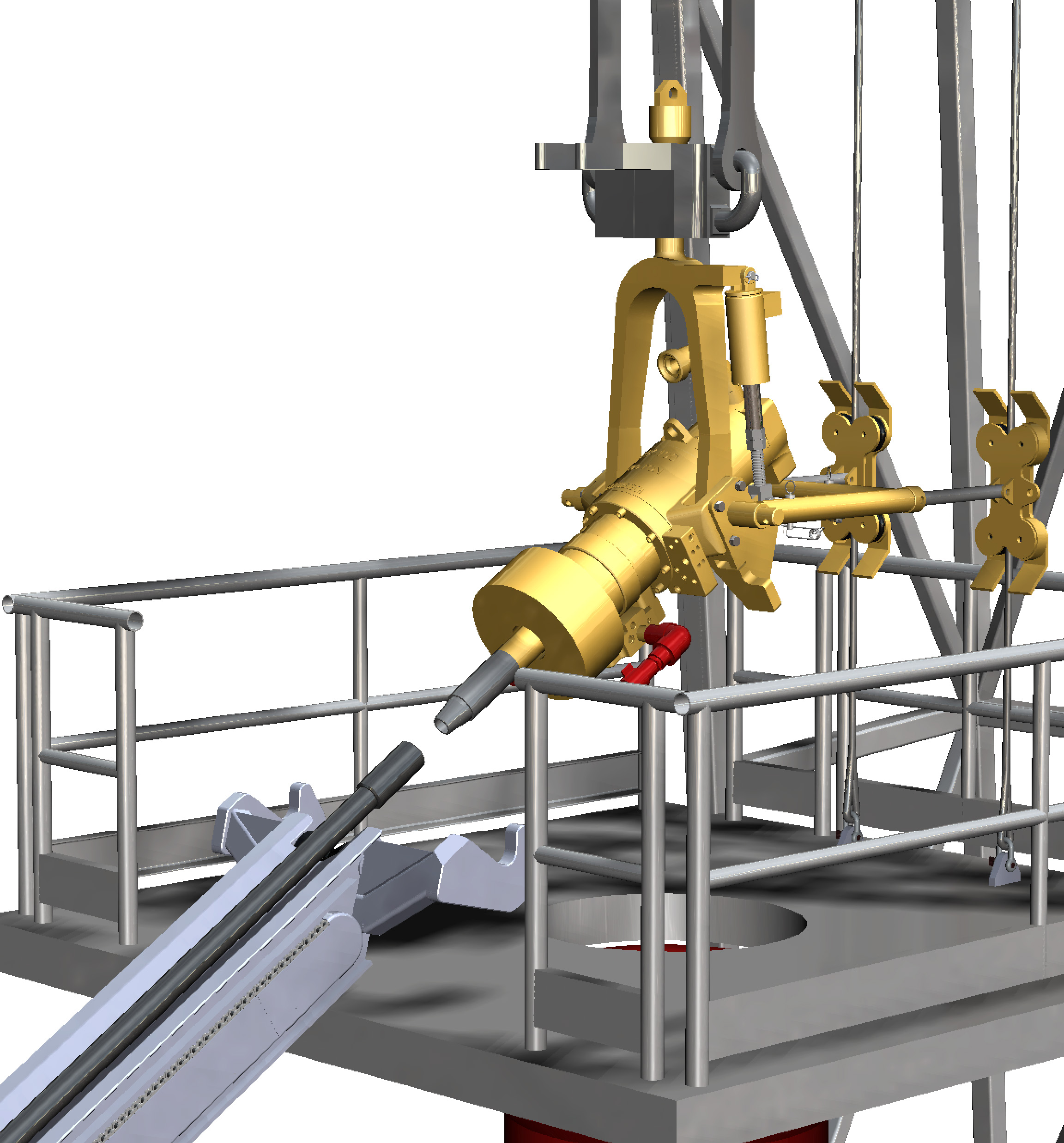

Now comes the Super Handler from Venturetech!