FillSafe Tank Filler Kits

This is the last thing your man sees when filling a tank!

Clearly marked Diesel and Hydraulic, this is another step toward keeping Diesel out of the Hydraulic tank!

Some customers have spent $25,000-50,000 to replace pumps and motors because of diesel in the hydraulic tank!

P/N 13364 ………for hydraulic oil reservoir

P/N 13394 ………for diesel tank, pre-Tier IV engines (vented cap)

P/N 13393 ………for diesel tank, Tier IV engines (non-vented cap)

ScopeDown Torque Track

Telescoping track scopes up and down with mast and lays down with mast for travel.

No track sections for men to unsafely rig up or down.

Swivel may be positioned to tilt toward any pipe handler location.

Same track is used for either XK-100 or XK-150 by changing only the swivel adapter.

Zero torque into mast. Torque reacts through welded mounts into Y-base. Rated for 12,000 ft-lbs.

Upper track hangs from crown and scopes down into square tube lower track.

Track latches out of the way for snubbing.

Work the string full track height if getting stuck.

Engineered to API-8C & API-Q1, safety factor 3:1 min.

Swivel parking rack for tripping is optional.

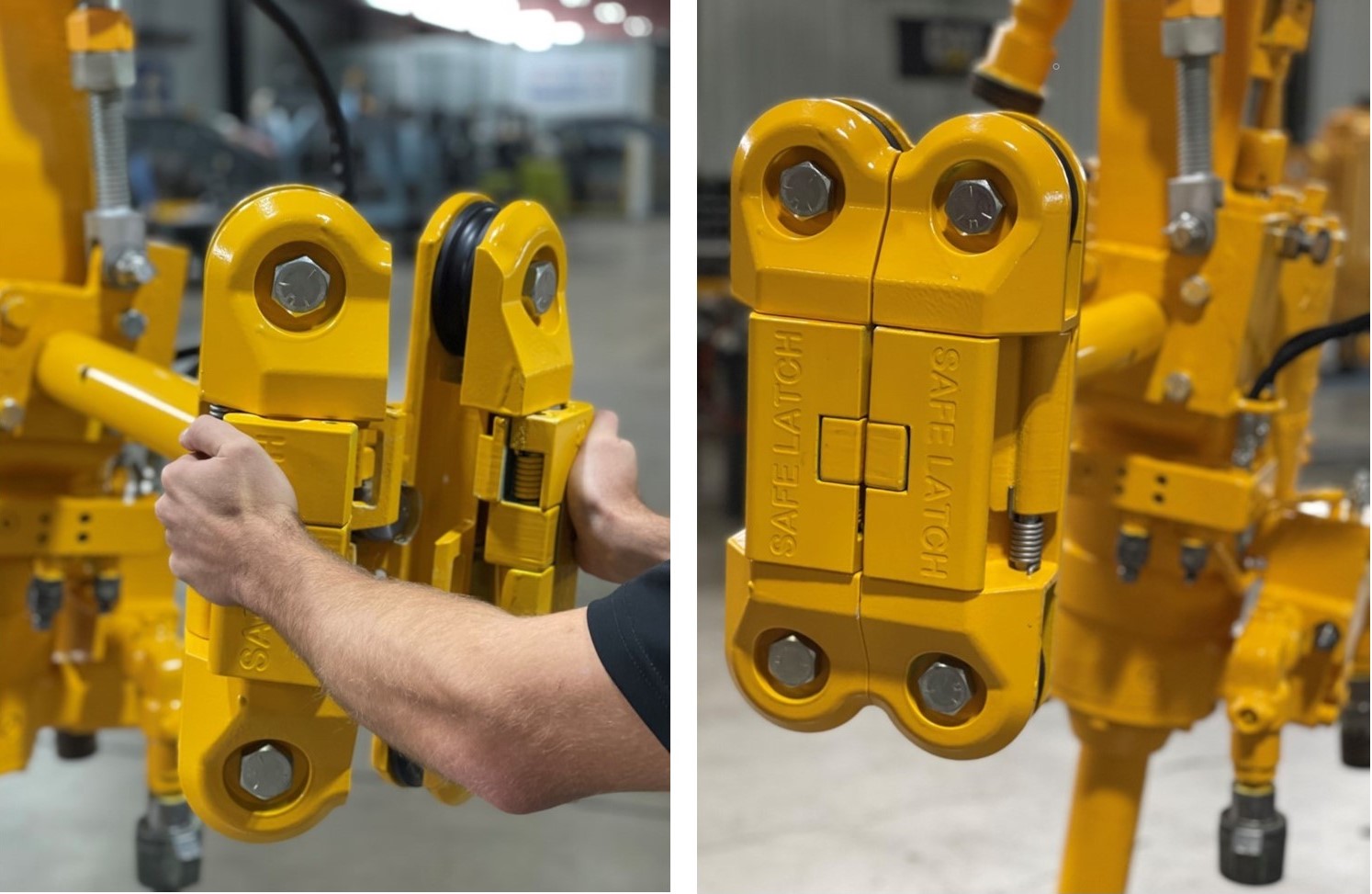

SafeLatch Torque Arms

Safe and quick to latch or unlatch from wire ropes.

No tools, loose parts, or falling objects.

Pull handles to unlatch and open.

Swing onto wire rope and close.

No need to remove torque arms from swivel for travel or rig up/down.

Only two arm lengths fit wire rope spacings from 5' to 10'.

SafeBreak Sub Breaker for Trailer

Keep your guys safe! Bad things happen when breaking subs against a pipe wrench!

Easy one-man operation using swivel torque to break connections.

For XK-100 and XK-150 - 12,000 ft-lbs rated.

Latches out of the way until needed.

Simple installation – Kit welds to swivel rack.

In case swivel power won't do the job, consider our Shop Floor Sub Breaker.

Safebreak Sub Breaker for Shop Floor

50,000 ft-lbs and up to 6-5/8” diameter. Use for swivels or any string of connections.

Hydraulic vise and tong can break at any connection, any length assembly.

Compact footprint – 4' X 4'

Easily movable with forklift or crane.

Safe – Includes protector wall for operator with bulletproof window.

Plug-in or hard wire to 3-phase 230/460 Volt source.

Inexpensive compared to monster machines.

RPM Readout Kit

FEATURES –

Simple rpm sensor on swivel.

Inexpensive hanging electric cable and connecting cable from panel to HPU - Cheap replacement.

Digital weatherproof RPM meter is intrinsically safe in compliance with hazardous requirements.

OPTION 1 – RPM METER BUILT INTO CONTROL PANEL

Includes rig floor control panel with digital RPM meter connected by inexpensive cable to electronics box on HPU.

Cable connector at the panel allows easy disconnection along with umbilical QD’s.

New power swivels will include RPM-ready panel to allow RPM meter installation when new or later.

Meter is backlit for easy readability at night.

OPTION 2 – LOOSE RPM METER, for mounting outside control panel

Same digital intrinsically safe RPM meter in weatherproof box for customer mounting.

Includes inexpensive cable to connect HPU sensor manifold to RPM meter.

Meter is backlit for easy readability at night.

OPTION 3 – NO RPM METER, wiring only

For customers with existing intrinsically safe 4-20mA system such as Pason.

Same HPU electronics but without control panel or RPM meter.

Includes inexpensive cable between HPU and rig floor.

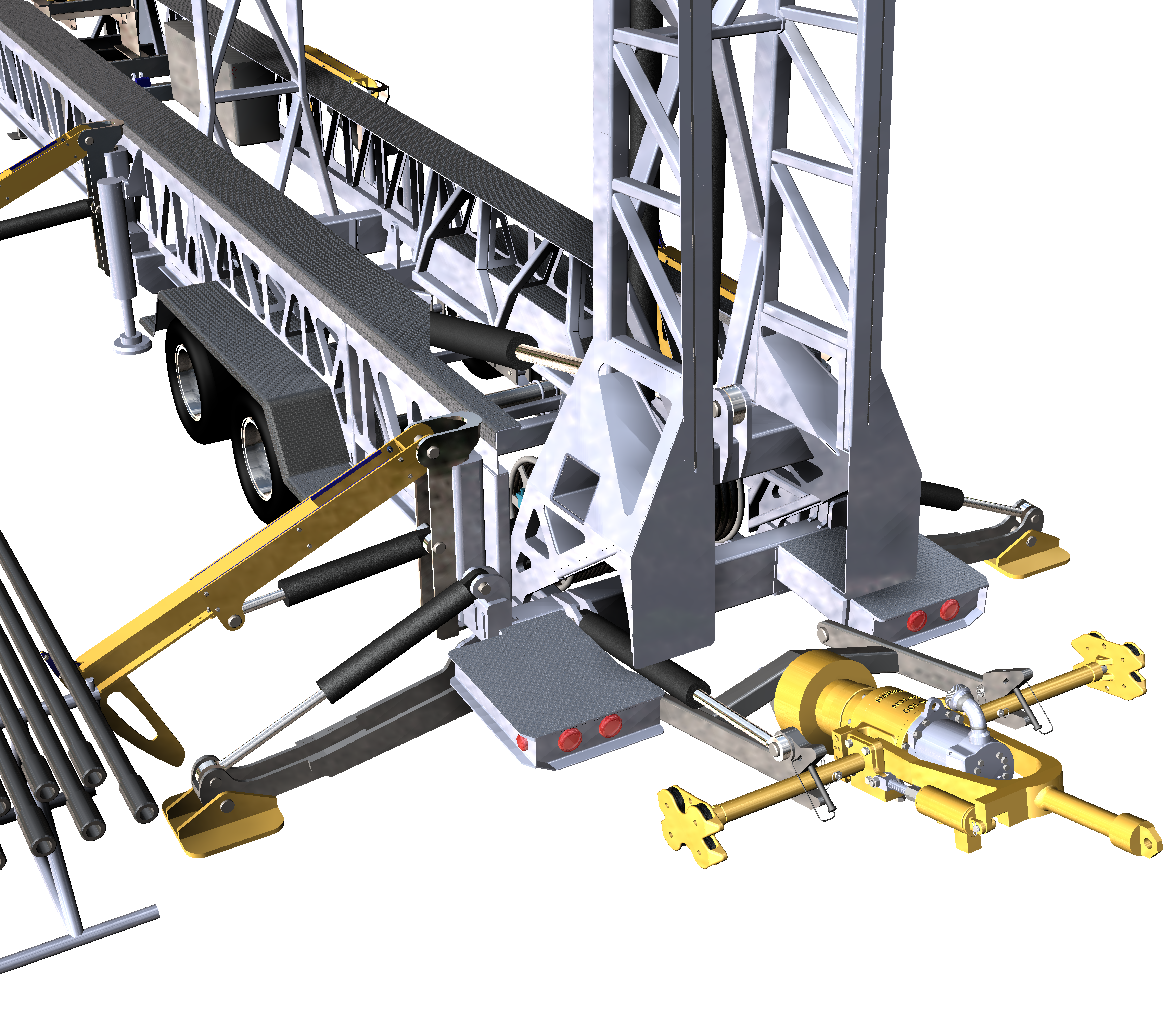

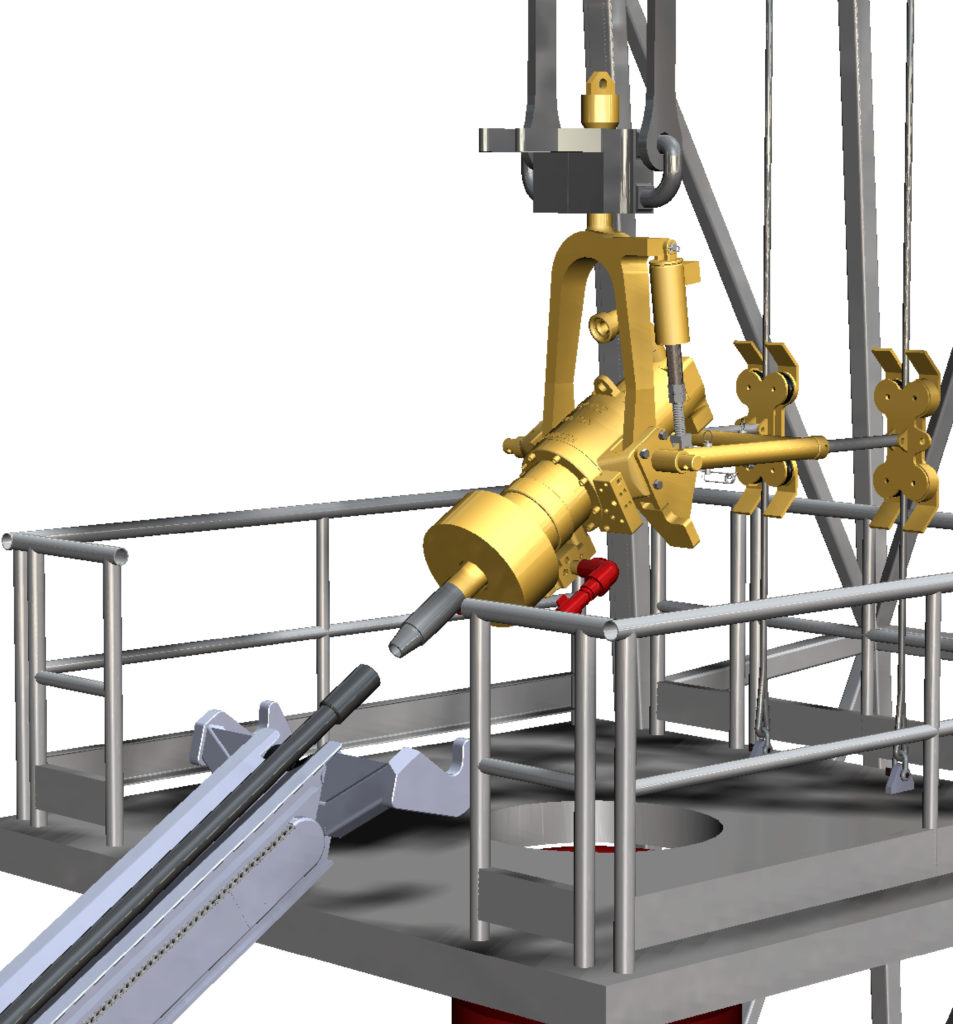

Super Handler

It's fun to Disrupt Technology!

The Super Handler™ is a radical pipe handler which includes either of our power swivels !

This is a major departure from the way things have been done before!

Combining our power swivels with a unique pipe handler brings many benefits. See list below!

Cuts costs, saves time, increases safety! Numerous patents issued.

Our customers say this will be a game-changer!

Sorry it's not on the market yet, but covid and the oil crash stopped our development.

Our patent coverage is already quite extensive and our engineering is more than half done.

But while markets were slow, we decided to develop the smaller and less expensive products shown here that could go to market sooner.

Cuts Total Costs

- Less initial cost than the two separate units of a pipe handler and a power swivel.

- Less operating cost than two separate units – fuel, insurance, etc.

- Less personnel cost than two separate units - only one driver/operator.

- Less maintenance cost than two separate units - only one trailer, one engine, one hydraulic system, etc.

- Less environmental impact – One truck, one trailer, one engine, one hydraulic system.

- Flexible usage – Rental companies can offer swivel and/or pipe handler services with one unit.

- Time Saving – Requires no dangerous pinning. Selector pins slip easily into place at ground level.

- Space Saving – Only one footprint on rig site.

- Fast Cycle Time - As fast as pipe is needed.

- 25’ horizontal reach without extension - Extendable trough is built into the unit.

- Range 3 pipe capacity without extension.

- Handles 3000 lb joints of pipe without adjustment.

- Engine is same as our XK-100 or XK-150 Power Swivel.

- XK-100 model tows with 3500 or 4500 truck, uses standard electric brake axles.

- XK-150 model tows with tractor and 5th wheel hitch, uses standard air brake axles.

Increases Safety

- Safe - For spin-up, driller presets swivel tilt to repeat same pipe angle every time.

- Safe - Torque Skate not only pushes and pulls pipe, it also holds light torque against swivel spin up so nobody tries to use a pipe wrench for backup.

- Safe - If spinup with swivel is not allowed by company policy, Torque Skate will spin up pipe onto the non-rotating swivel pin.

- Safe - Super Handler moves power swivel, hoses, and control panel to and from rig floors up to 40' high. No winching.

- Safe - 25’ horizontal reach with no extensions required.

- Safe - Handler also moves misc equipment and tools to and from rig floor safely – up to 3000 lbs.

- Safe - When swivel is not in use, it may be hydraulically stored in parking position behind bumper.

- Safe - Only one driver, truck, and trailer instead of two.

- Safe - Rig floor heights to 40’ are selected at ground level and require no dangerous pinning.

- Fail Safe – Backups or locks on all movements.

- Safe Design Specs – API 8C, 4F, 2C, AISC, ASME, SAE, DOT