Skip to content

Cuts Costs

- Less initial cost than two separate units – a pipe handler and a power swivel

- Less operating cost than two separate units – fuel, insurance, etc

- Less personnel cost than two separate units - Only one driver/operator

- Less maintenance cost than two separate units - Only one trailer, engine, hydraulic system

- Less Environmental Impact – One truck, one trailer, one engine, one hydraulic system

- Flexible usage – Rental companies can offer either/both swivel or pipe handler services with one unit.

- Time-Saving – Unique structure requires no dangerous pinning, just easy selector pins.

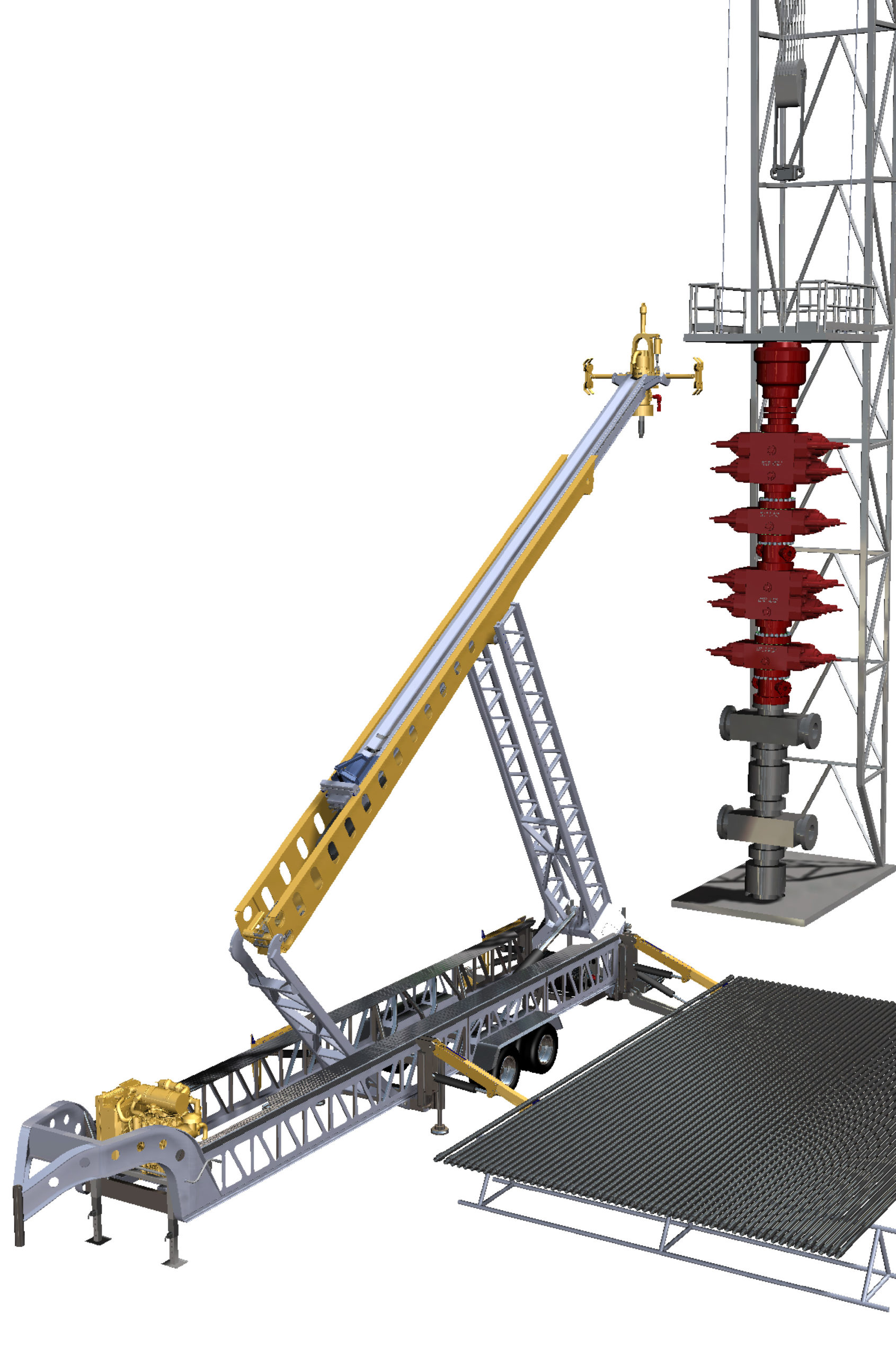

- Space Saving – Only one footprint on rig site

- Cycle Time - 25-35 seconds depending on height, as fast as the rig can move pipe

- High Reach - 40’ reach for the highest rig floors – no extension required

- Range 3 pipe capacity – no extension required

- Handles 3000 lb joints of pipe up to 13-3/8” casing without adjustment

- Power – Same Caterpillar Diesel as our XK-100 power swivel

- Tow with 3500 or 4500 truck - Electric Brakes

Increases Safety

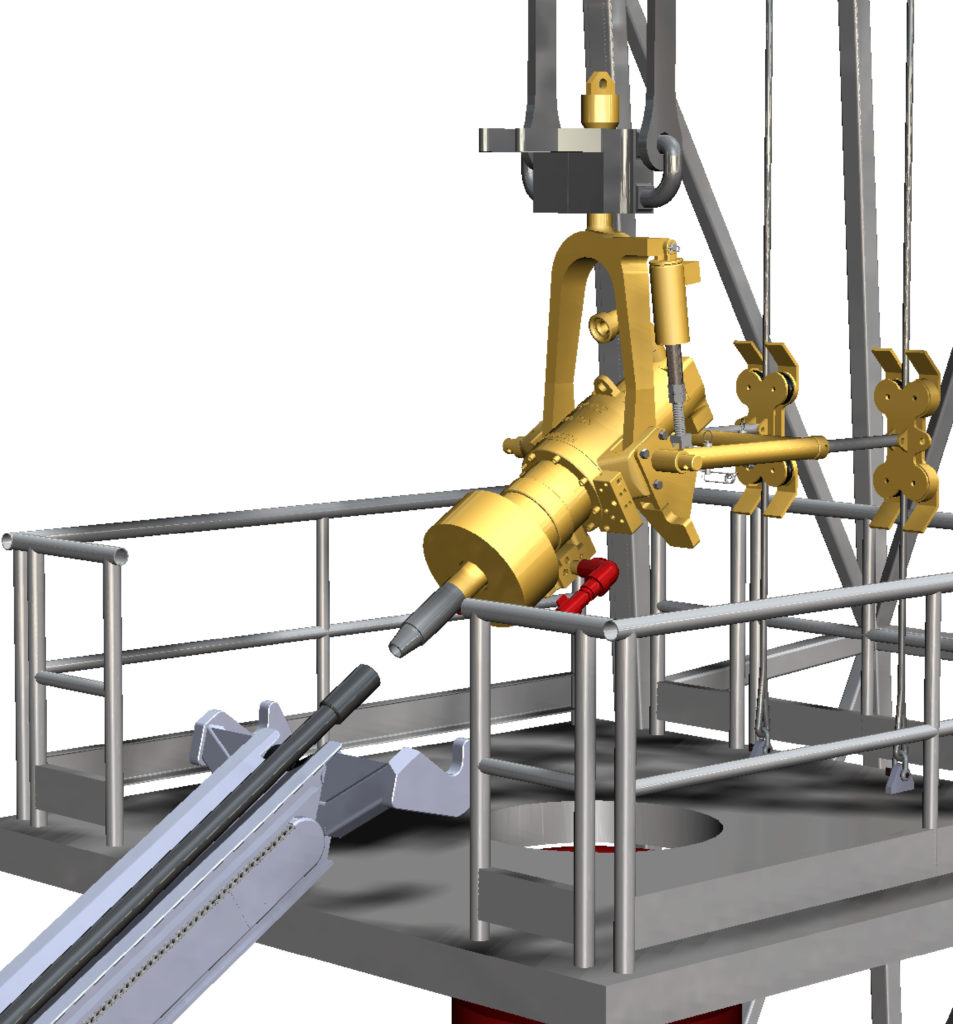

- For spin-up, the swivel is preset to tilt repeatably to the handler pipe angle.

- Spin-up torque is held by a soft pipe grabber on the handler.

- Handler moves power swivel and control panel to and from rig floor safely – No winching required.

- Handler also moves misc equipment and tools to and from rig floor safely – up to 3000 lbs

- When swivel is not in use, it moves out of the way to the parking position.

- Only one driver, truck, and trailer on the road instead of two.

- Height adjustment to 40’ requires no dangerous pinning and no extensions.