Top drives are automated drilling and pipe handling systems that make rig floor operations faster and safer.

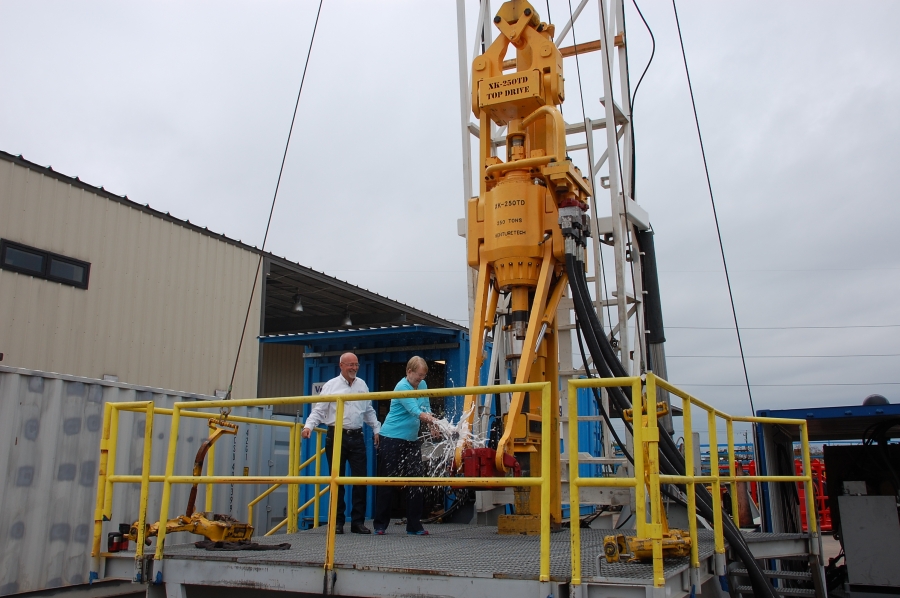

After 20 years leading the field in power swivels, Venturetech entered the Top Drive business. So far we have received 20 patents related to simplicity and reliability, and we are out to reduce down time and increase safety.

DRILLING PERFORMANCE FROM FIELD DATA

Our XK-250 power swivel has been used as a top drive for many years and our new simplfying patents have been issued.

For about 10 years, ten SuperSingle rigs with Venturetech XK-250's* drilled wells in the Fayetteville Shale basin.

55 to 60 wells per year were drilled averaging less than 6 days per well.

Laterals reached to 10,000 ft, measured depths to 15,000 ft.

Drilling was maintained at 100-120 rpm and 18,000* ft/lbs continuous torque with weights exceeding 300,000 lbs.

Total equipment downtime ran less than 7 hrs per month or less than 1% per rig.

To put that into perspective, the standard IADC contract permits contractors 24 hours per month or 3% downtime before penalizing the day rate. Most contractors are down more than that.

(* Our former XK-250 power swivel used the same hydraulic motor as the new ZK-150 Top Drive so same performance.

But the new ZK-250 Top Drive uses a larger hydraulic motor rated at 35,000 ft-lbs so continuous torque is 26-30,000 ft-lbs. )

BASIC DESIGN

The architecture of our top drives is patterned after our field-proven line of power swivels. So they also have the simplicity of no gears, using one hollow shaft hydraulic motor splined directly to the stem.

Features include a dual load path to prevent tripping loads on the thrust bearing, and elevator kickout to reach out and pick up drill pipe from the mousehole or V-door.

Many other innovations are listed below, making the Venturetech top drives a new standard in the industry. Nearly 20 patents have been issued related to simplicity, reliability, and reducing downtime.

INNOVATIONS

1. Patented 10,000 psi washpipe seal assembly with quick-change washpipe. This unique invention is auto-lubricating and provides long seal wear life during high pressure long reach drilling.

2. Patented recirculating oil circuit with numerous features.

a. This circuit cools the hydraulic motor and load bearings when it’s hot outside. In winter it also warms the oil before startup.

b. It also cools and lubricates the bearings with 10-micron filtered oil so there is no worrisome gear oil level to top off and contamination of the oil is eliminated.

c. This patented oiling system also powers the top drive’s pipe handling functions, thus reducing hanging hoses.

3. A patented hydraulic backup wrench with a single enclosed hydraulic hose holds the drill pipe against make or break torque and may be operated remotely up in the derrick if required by downhole conditions.

4. Patented AirLift® air-suspended thread compensator allows the top drive weight to float, preventing thread damage. No hydraulic cylinders, accumulators, hoses, or fittings to leak and cause shutdown. Only one air valve, same as your tires, with tire reliability.

5. Patented hydraulic-actuated IBOP provides wellbore safety and serves as a mudsaver to minimize mud loss on the rig floor. Manual backup is included.

6. To react torque, a patented slide assembly rides on a rugged torque track hung between crown and floor. No torque loads are seen by the derrick. One man hanging in a bosun’s chair with a 2” wrench can quickly and safely make or break the patented track sections. First-time torque track rigup includes permanent attachment of our universal base plate to heavy structure, plus welding a padeye under crown for hanging the track.

DIESEL-HYDRAULIC POWER UNIT

All power unit components including engine, pump, tank, controls, and oil cooler are fully integrated into a well-lit, weathertight skid-mounted container. Power units include a Caterpillar C-18 diesel engine driving a variable-displacement piston-type hydraulic pump. Engine radiator is equipped with a blower-type fan to blow heat out of the house, and the oil cooler also discharges hot air outside. When doors at each end are closed, container is smooth outside. Hydraulic reservoir is designed to maximize floor space and service access, and electric heaters are built in to the reservoir. These heaters and the oil circulating system allow warm oil to circulate before starting the engine and pump in cold weather. A flow-thru diesel tank is included for connection to rig's central fueling system.