Est. 1980 - hydraulic drilling machinery worldwide

SafeLatch™ Torque Arms

Quick on and off wire ropes.

No tools, loose parts, or falling objects.

Double latched, double locked.

Pull handles to unlatch and open, swing onto wire rope to lock closed.

Will finally be in stock first quarter 2024, and will be standard on the XK-100 and XK-150.

Easy safety update for all your XK swivels.

Hardened and plated steel sheaves with oil-less bronze bushings require no lubrication. Now in stock. Direct replacement for urethane sheaves.

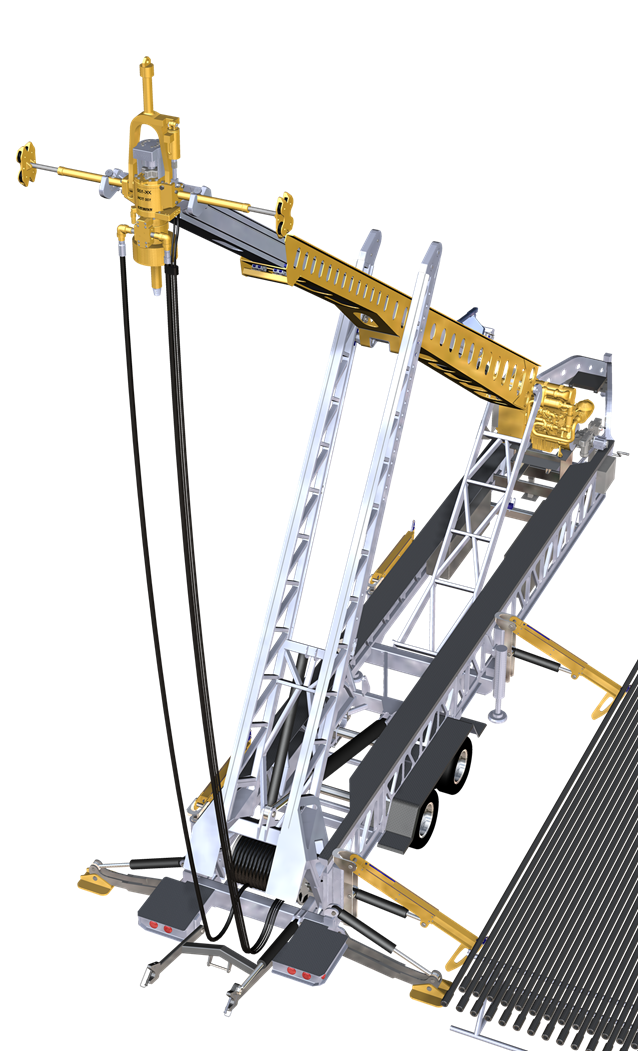

ScopeDown™ Torque Track

Works with any telescoping doubles mast, rig floors to 40' high.

Telescoping track scopes up and down with mast. No work required at rig-down.

Track lays down with mast for travel. No work required at rig-down.

Swivel may be positioned toward front or driller side V-door location. No rig-down required.

Track fits both XK-100 and XK-150 swivels. To change swivel, no rig-down required.

Zero torque into mast. Rated for 12,000 ft-lbs. Torque reacts into carrier structure thru Mantis Reactor™.

Engineered to API-8C & API-Q1, safety factor 3:1 min.

Super Handler™

The Super Handler™ is a unique pipe handler which includes the XK-100 or XK-150 power swivel.

Our customers say this will be a game changer!

Designed to greatly increase safety, save time, and cut costs!

Patents issued and pending.

We put all the smaller new products ahead when covid crash occurred, but the Super Handler is still coming!

ZK Hydraulic Top Drives

Top drives are big power swivels for the drilling industry. But top drives also include many automated drilling and pipe handling functions plus a torque track to react the torque.

Our hydraulic top drives are a logical development of our decades of hydraulic power swivel experience.

Our designs are about simplicity.

XK Power Swivels

Power swivels are drilling machines for the well servicing industry. They include at least 3 functions:

- Rotation of the pipe

- Support the hanging pipe

- High pressure sealing to conduct the mud pump flow down through the rotating main shaft and drill pipe.

Other features and options include: Swivel Tilt, Torque Track, SafeLatch Torque Arms, 10,000 psi Washpipe Seal Assy, Brake, and SafeBreak Unit.

What's going on at Venturetech?

Here are a few shots of what's happening at Venturetech. Take a look.